- Quick Look at the 2020 Volkswagen Atlas Cross Sport | MotorTrend - March 13, 2024

- BMW Design – 2009 BMW Z4 – 2009 Detroit Auto Show - March 11, 2024

- Top 10 Car Features Women Love - October 7, 2023

Volvo is adopting a process called “mega casting” for aluminum parts in order to simplify manufacturing of future electric vehicles.

Mega casting will be implemented at Volvo’s Torslanda, Sweden, factory as part of a $1 billion investment to upgrade the plant for EV production, Volvo said last week.

The process involves use of large single aluminum castings for major components, such as the floor structure. This reduces weight (helping to improve range and efficiency) and allows designers to make better use of interior space, according to Volvo. Mega casting also reduces manufacturing complexity, which will lead to cost savings and a lower environmental impact, Volvo claims.

Volvo mega casting

It also sounds similar to what Tesla is planning to implement at its new Texas factory, beginning with the Model Y. Tesla CEO Elon Musk has repeatedly mentioned the new cast-body process as a way to improve profitability and scale up production faster.

Other upgrades to the Torslanda factory include new machinery and painting processes for the plant’s paint shop, which Volvo claims will reduce energy use and emissions.

A new battery assembly plant will place cells into modules and packs, while the assembly area will be modified for EV-specific processes, such as marrying the battery pack to the vehicle structure. The plant’s logistics area will also get upgrades to optimize the flow of parts.

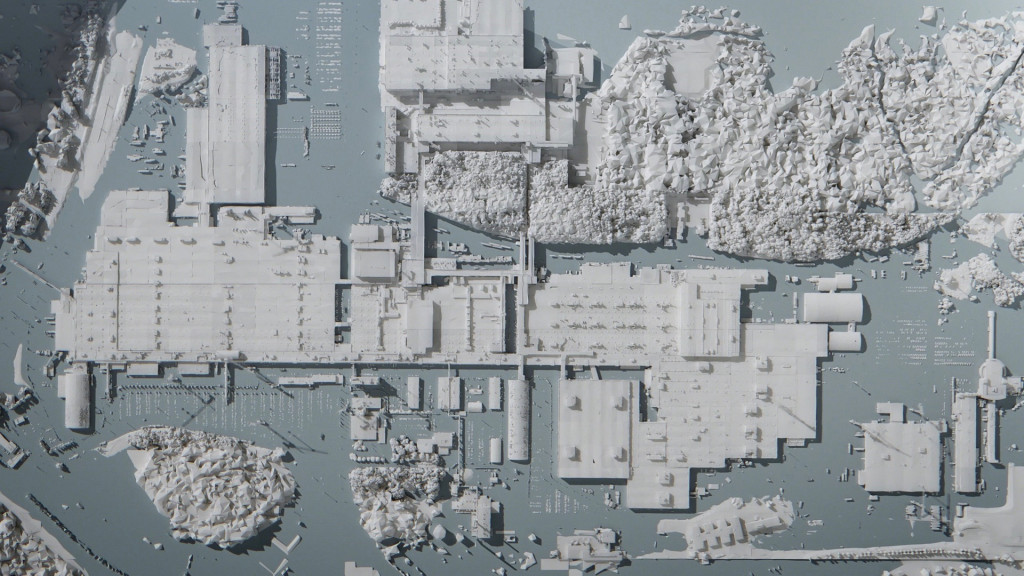

Overhead rendering of Volvo Torslanda factory

Opened in 1964, the Torslanda factory currently has an annual production capacity of 300,000 cars. That makes it the automaker’s largest plant, and it was once the largest single workplace in Sweden, Volvo claims.

The announcement of EV-production upgrades at Torslanda comes shortly after Volvo announced plans for joint-venture battery plant with Northvolt to be built nearby the Torslanda factory. Scheduled to open in 2025, it will have a “potential” annual cell production capacity for 500,000 EVs, Volvo claims.

Volvo’s two current electric models are the XC40 Recharge and C40 Recharge compact crossovers. An electric XC90 successor, rumored to be called Embla, is expected to arrive later this year. Volvo may also launch an entry-level electric crossover positioned below the XC40 and C40.